Sometimes no is not an option. We then often turn to Google hoping for an answer and that answer sometimes is that part is not longer available and does not exist on the open market.

Sometimes no is not an option. We then often turn to Google hoping for an answer and that answer sometimes is that part is not longer available and does not exist on the open market.

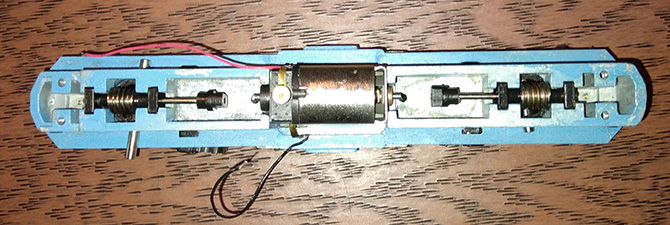

The customer has an older Bachmann HO locomotive with cracked and broken drive couplers from the 1950's. It is his adult son's locomotive and hoped to surprise him with the repair as a gift.

After an extensive internet search revealed no replacement parts were to be had, it seemed like the next step was to have a replacement part made to order.

We reviewed the detailed information, photos and sketch provided by the client. It was clear that the original pot metal drive coupler was fatigued/cracked and its friction fit no longer had any bite on the drive shaft.

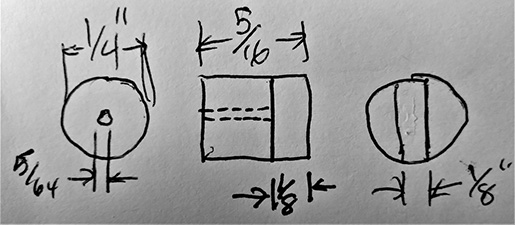

After a brief consultation with the client, it was agreed that the client would leave the Bachmann HO locomotive with us, at Next Dimension Fabworks, so we could model a reaplcement drive coupler and 3D print four friction fit ABS parts and four slip fit ABS parts. It was not clear which fit would work best when glued to the motor shaft. You can see in the sketch below these parts are small at just 1/4-inch by 5/16-inch in size.

In the end we decided that a natural white ABS material would be a good place to start since there are industrial glues that will bond ABS to Steel. Additionally if the ABS part proved to be a no go on operation then we also had the option to have this part made from Aluminum traditionally or via Laser Metal Sintering from our 3D Model. The aluminum parts would have been nearly seven times more expensive to create than the 3D printed ABS. It was clear the ABS was the starting point of this project.

After the part was modeled, we printed single test parts to ensure the friction fit was tight and the slip fit would slip. Once happy with our fitting we printed the final parts in ABS and the client picked the parts from our Naperville office. Total turn time was about 3 days from start to finish.

The client followed up with us to confirm that the replacement Bachmann HO locomotive Drive Coupler's we created were a good fit and the locomotive is now running on its tracks again.

When the manufacturer is no longer in business and 3rd party replacement parts are not available Next Dimension Fabworks can create a new part by measuring and fitting to meet the functional and material need of the part. Call or email us today!